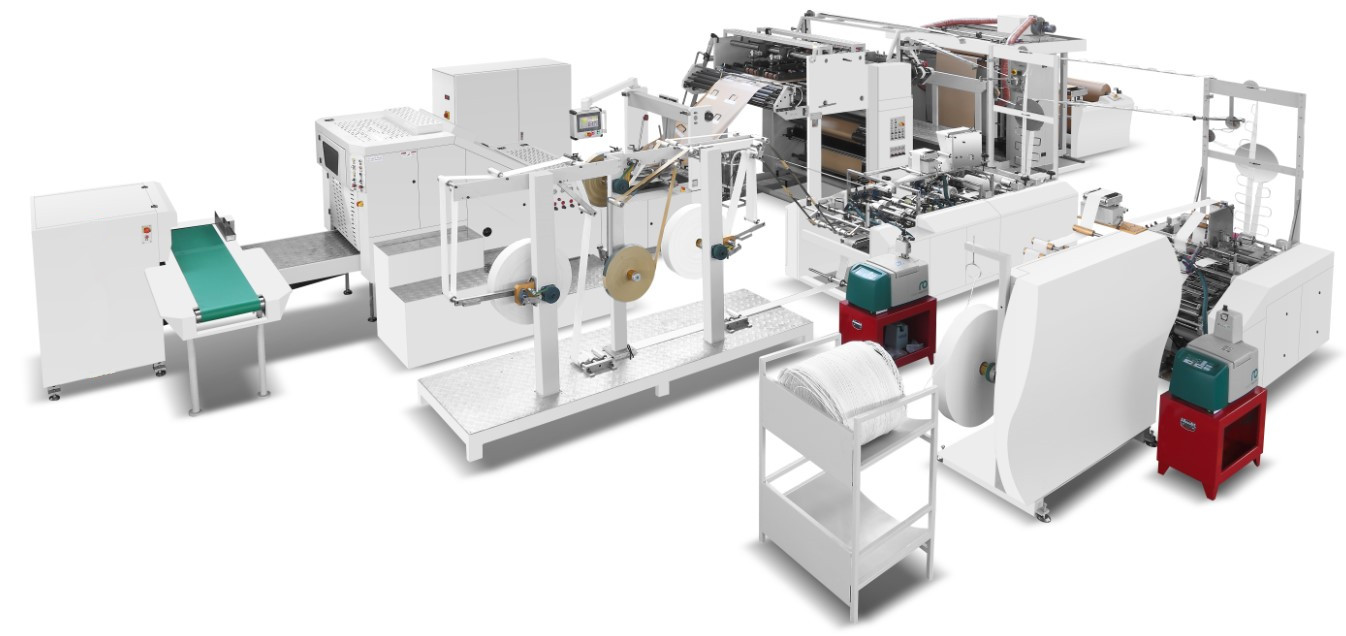

Roll-fed 330T/F Automatic Square Bottom Paper Bag Machine with Handle inline 2/4 colors printing machine

Roll-fed 330T/F Automatic Square Bottom Paper Bag Machine with Handle inline 2/4 colors printing machine

330T/F Fully automatic square bottom paper bag machine is designed for the production of paper bags with twisted handles. It is suitable for mass production of shopping bags in industries such as food and clothing. The one-line process consists of twisted handles making from paper rolls and twisted rope, delivery of handles to paste unit, pre-cutting of paper on position of rope, patch position gluing, handle pasting, and paper bag making. The paper bag making process consists of side gluing, tube forming, cutting, creasing, bottom gluing, bottom forming and bag delivery. This machine adopts German imported high-speed motion controller (CPU), which controls the operation of servo through high-speed bus to ensure stable movement and smooth motion curve. It is the automatic square bottom paper bag equipment with handles inline preferred by the majority of printing and packaging manufacturers.

Main features:

1.Use France SCHNEIDER touch screen human-computer interface, making the machine easy to operate and control.

2.Adopt Germany original LENZE PC control, integrated with optical fiber. Thus ensure stable and high speed running.

3.Adopt Germany original LENZE servo motor and German original SICK photoelectric eye correction, tracking printing bag accurately.

- Raw material loading adopts hydraulic auto-lifting structure. Unwind unit adopts auto tension control.

5.Raw material unwinding EPC adopts Italy SELECTRA, reducing material alignment time.

The main features of flexo printing :

1.The ink is transported by a separate gear motor, and the ink pump circulates the ink.

2.Use a closed scraper to scrape ink, ensure high-speed printing and prevent ink splash

3.Pneumatic lift and drop mode, automatically start after shutdown, automatically transport ink after printing plate installation,Printing plate automatic printing after booting

4.Independent closed type hot and cold dual function drying system

Main Electrical Components List

| Model | 330T/F |

| Cutting length | 270-530mm |

| Cutting length | 270-430mm |

| Bag width | 120-330mm |

| Bag width | 200-330mm |

| Bottom width | 60-180mm |

| Paper Thickness | 60-150g/㎡ |

| Paper Thickness | 80-150g/㎡ |

| Paper roll width | 380-1050mm |

| Paper roll width | 570-1050mm |

| Roll paper diameter | ф1300mm |

| Paper core | ф76mm |

| Patch length | 152mm |

| patch width | 50mm |

| Handle length | 320/340mm |

| Handle distance | 75mm |

| Rope diameter | Ф3-5mm |

| Patch paper roll width | 100mm |

| patch paper roll diameter | ф1200mm |

| patch paper thickness | 120g/㎡ |

| production speed for bags with handles | 30-150bags/min |

| production speed for bags without handles | 30-180bags/min |

| Machine Speed | 30-200bags/min |

| Cutting knife | Sawtooth cutting |

| Printing area | |

| Printing width | 100-1260mm |

| Printing length | 270-800mm |

| Printing speed | 10-100m/min |

| Color accuracy | ≤±0.20mm |

| Plate thickness (Including the thickness of the double-sided tape) | 2.28mm+0.38mm |

| Working Air Current | More than 0.36m³/ minutes, 0.5-0.8 MPa |

| Power Supply | 380V 3Phase

2 colors:380V 3Phase 52KW 4 colors:380V 3Phase 55KW |

| Machine weight | 2 colors:19T

4 colors:19.7T |

| Machine size | 2 colors:17000*8000*2500mm

4 colors:18500*8000*2800mm |

| Control System | |||

| Name | QTY | Original | Brand |

| CPU Program Controller | 1 | Germany | LENZE |

| PLC Power module | 1 | Germany | LENZE |

| PLC Input module | 2 | Germany | LENZE |

| PLC Point card | 1 | Germany | LENZE |

| Main power filter | 1 | Germany | LENZE |

| Human-computer touch screen interface | 1 | France | SCHNEIDER |

| Servo Motor | 8 | Germany | LENZE |

| Servo Motor Reducer | 8 | Germany | Alpha |

| Servo driver | 6 | Germany | LENZE |

| Bag forming frequency converter | 1 | Switzerland | ABB |

| Bag forming motor | 1 | Taiwan | |

| Photoelectric eye for printed-bag tracking

|

1 | Germany | SICK |

| Optical fiber communication separator | 1 | USA | |

| Low voltage electrical apparatus | 1 | France | SCHNEIDER |

| Photoelectric sensor | 1 | USA | BAUMER |

| Pneumatic component | 1 | Taiwan | |

| Auto lubricating | 1 | China | |

| Air conditioner for electric control box | 1 | China | |

| Deviation correction and tension control system | |||

| Name | QTY | Original | Brand |

| EPC controller | 1 | Italy | SELECTRA |

| Servo motor for EPC | 1 | Italy | SELECTRA |

| Ultrasonic sensor | 1 | Italy | SELECTRA |

| Magnetic powder brake | 1 | China | WEIZHENG |

| Automatic Tension System of Magnetic Powder | 1 | Germany | LENZE |

| Automatic Hydraulic Feeding Motor | 1 | Taiwan | |

| Feeding hydraulic cylinder | 1 | China | |

| Transmission | |||

| Name | Qty | Original | MTED |

| Synchronous belt | 1 | China | BELDI |

| Synchronous wheel | 1 | China | MTED |

| Bearing | 1 | Germany | FALA |

| Guide roller | 1 | China | BAIXIAO |

| Gear | 1 | China | MTED |

| Glue position | |||

| Name | Qty | Original | MTED |

| Bottom glue (bottom-sealing white latex) | 1 | China | MTED |

| Motor for bottom glue evening | 2 | China | |

| Pneumatic auto glue filling valve | 2 | China | |

| Glue Glue Position Detection | 1 | Switzerland | BAUMER |

| Spraying gun for center sealing (dense adjust Glue gun ) | 1 | China | MTED |

| High-pressure glue barrel for white latex | 2 | China | MTED |

| Handle Pasting Unit | |||

| Name | Qty | Original | Brand |

| EPC controller | 2 | Italy | SELECTRA |

| Servo motor for EPC | 2 | Italy | SELECTRA |

| Ultrasonic sensor | 2 | Italy | SELECTRA |

| Hot Melt Glue Device | 1 | Switzerland | RO |

| Hot Melt Glue Gun | 2 | Switzerland | RO |

| Hot Melt Glue Gun | 2 | Switzerland | RO |

| Hand-held servo motor | 1 | Germany | lenze |

| Hand-held Servo Driver | 1 | Germany | lenze |

| Pasting Unit | |||

| Name | Qty | Original | Brand |

| EPC controller | 2 | Italy | SELECTRA |

| Servo motor for EPC | 2 | Italy | SELECTRA |

| Ultrasonic sensor | 2 | Italy | SELECTRA |

| Hot Melt Glue Device | 1 | Switzerland | RO |

| Hot Melt Glue Gun | 4 | Switzerland | RO |

| Hot Melt Glue Gun | 4 | Switzerland | RO |

| Hand-held servo motor | 1 | Germany | lenze |

| Hand-held Servo Driver | 1 | Germany | lenze |

| Printing Area | |||

| Name | Qty | Place of Origin | Brand |

| Frequency transformer | 1 | China | Inovance |

| Main motor | 1 | China | |

| Ink motor | 1 | China | |

| low-voltage apparatus | 1 | France | Schneider |

| Main roller bearing | 1 | Japan | |

| Guide Roller bearing | 1 | China | |

| Name | Size | Download |

|---|---|---|

| 330-T-F-description.pdf | 351 KB | Download |

Also Offers

Contact Volmas Packaging

Get in touch with us today to discuss your project and how we can help you fully realise its potential.

Volmas Packaging

51 Kaifayi 1st Rd. Ruian, Zhejiang, 325200, China

+86 186-0666-8229

+86 186-0666-8229

info@volmas.com